HEPA Filter, Types, Maintenance, Certification

Table of Contents

HEPA Filters (High Efficiency Particulate Air Filter)

What is a HEPA filter?

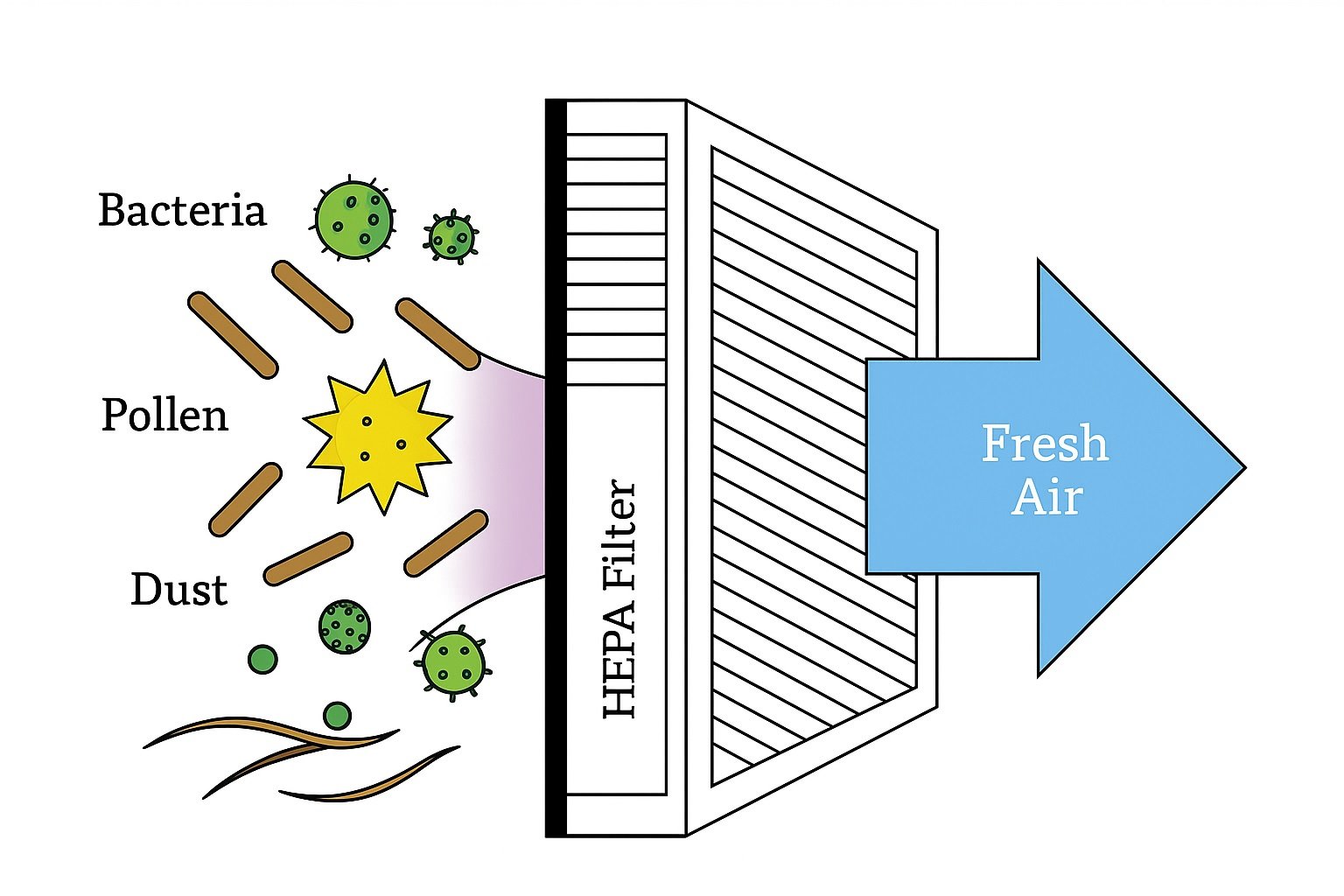

- HEPA stands for High-Efficiency Particulate Air filter. It is a specialized filter designed to remove:

- ≥99.97% of airborne particles ≥0.3 microns in size (including bacteria, mold spores, dust, and some viruses).

HEPA filter role in Laminar Flow Hoods

- The HEPA filter is positioned near the back (horizontal hood) or top (vertical hood).

- Room air is first pulled through a pre-filter (removing large dust/debris), then through the HEPA filter.

- Only ultra-clean, filtered air is blown across the work surface in a laminar flow hood (smooth, unidirectional) flow to protect sterile products.

Characteristics of HEPA Filters

✅ High filtration efficiency✅ Low airflow resistance (allows continuous airflow)

✅ Long service life (but must be checked regularly)

✅ Fragile surface — never touch or wipe directly during cleaning

✅ Essential for meeting USP <797> standards for sterile compounding

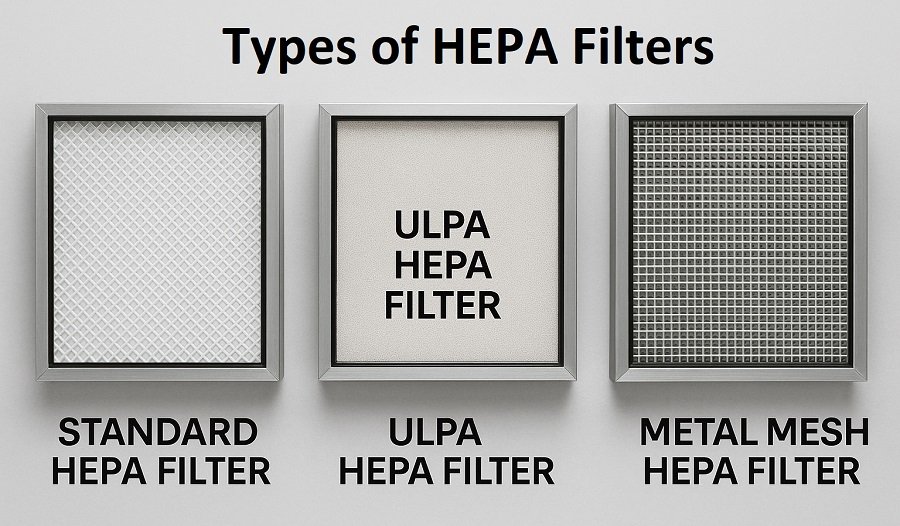

Types of HEPA Filters

1. Standard HEPA Filters

- Defined to remove ≥99.97% of particles ≥0.3 microns.

- Used in most pharmacy laminar flow hood, cleanrooms, biological safety cabinets, and hospital isolation rooms.

- Provides ISO 5 air quality when installed properly.

2. ULPA Filters (Ultra-Low Penetration Air)

- Higher-efficiency than HEPA: removes ≥99.9995% of particles ≥0.12 microns.

- Used in industries requiring extreme particle control (e.g., semiconductor manufacturing).

- Not typically required in pharmacy hoods, as HEPA meets USP standards.

3. Metal Mesh or Pre-Filters (paired with HEPA)

- Not HEPA themselves but used upstream to trap large particles, extending the HEPA filter’s lifespan.

4. Custom or Specialized HEPA

- Some systems may use HEPA with added carbon or chemical filtration layers to control vapors or odors (mostly in chemical or hazardous drug setups).

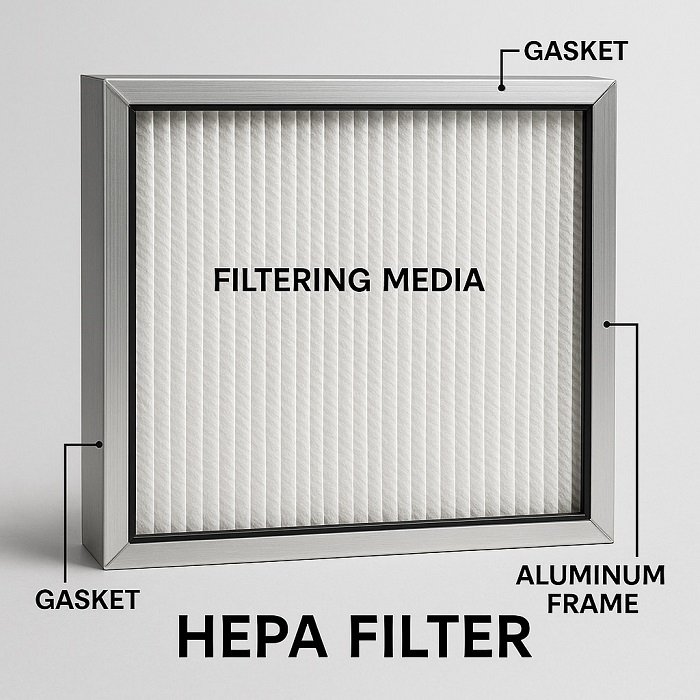

Components of HEPA Filters

HEPA Filter Media (Core Material)

- Material: Glass fibers (most common) or synthetic fibers (e.g., polypropylene).

- Fibers are randomly arranged in a dense, non-woven matrix.

- Function: Captures particles via three mechanisms:

- Interception (particles stick to fibers).

- Impaction (larger particles collide with fibers).

- Diffusion (tiny particles move erratically and get trapped).

- Must meet 99.97% efficiency at 0.3 microns (true HEPA standard).

Pleated Design

- Structure: Filter media is folded into accordion-like pleats.

- Purpose: Increases surface area for particle capture without significantly restricting airflow.

Frame (Support Structure)

- Materials: Plastic, aluminum, or stiff cardboard.

- Function: Provides structural integrity.

- Ensures a tight fit in air purifiers/HVAC systems to prevent air bypass.

Gasket/Seal

- Materials: Foam, rubber, or adhesive strips around the edges.

- Function: Prevents air leakage around the filter edges, forcing all air through the HEPA media.

Pre-Filter (Optional but Common)

- Material: Polyester mesh or non-woven fabric.

- Function: Traps large particles (dust, pet hair, lint) to prolong the HEPA filter’s lifespan.

- Often washable/reusable.

Post-Filter (Optional Add-Ons)

- Activated Carbon Layer: Adsorbs odors, VOCs, and gases (e.g., smoke, chemicals).

- Antimicrobial Treatment: Coated with silver ions or other agents to inhibit mold/bacteria growth on the filter.

Support Grid or Mesh (For Stability)

- Material: Plastic or metal mesh (often in thicker HEPA filters).

- Function: Prevents the pleated media from collapsing under high airflow pressure.

Core (For Cylindrical HEPA Filters)

- Structure: Some HEPA filters (e.g., in vacuums) have a cylindrical design with a hollow core.

- Function: Maximizes airflow while maintaining filtration efficiency.

HEPA filters Certification, Recertification and replacement

HEPA Filters Certification

- Done at installation of the HEPA filter or equipment (e.g., laminar hood, cleanroom)

- Includes airflow velocity tests, particle counts, HEPA integrity (leak) tests, and pressure differential checks

HEPA Filters Recertification

- Per USP <797> and <800>,

- HEPA filters must be certified every 6 months (semiannually)or after repairs/movement.

- Also required:

- After relocation of equipment

- After filter replacement or repair

- After major maintenance or contamination events

HEPA Filters Replacement

- No fixed replacement schedule, and gets replaced only when performance fails, such as:

- Failed airflow, particle count, or integrity test

- Excessive pressure drop (filter clogging)

- Physical damage or visible contamination

HEPA Filters Testing

HEPA Filter Testing

1. Airflow Velocity Testing

- Measures the speed of air (typically in feet per minute, fpm) at the filter face or work zone.

- Ensures uniform laminar airflow and verifies that air meets required ISO class (e.g., ISO 5).

2. Airflow Pattern (Smoke) Testing

- Uses smoke visualization to confirm airflow moves clean-to-dirty and prevents turbulence or backflow.

- Helps identify dead spots or airflow disruptions.

3. HEPA Filter Integrity (Leak) Testing

- Uses an aerosol challenge (e.g., PAO or DOP) upstream and measures downstream for leaks.

- Detects pinholes, seal defects, or frame leaks.

4. Particle Count Testing

- Measures airborne non-viable particles (e.g., ≥0.5 µm) in the cleanroom or hood.

- Confirms compliance with ISO 5, ISO 7, or ISO 8 classifications.

5. Pressure Differential Testing (for rooms, not hoods)

- Checks room-to-room pressure to ensure directional airflow (positive or negative as required).

What HEPA Filters Capture:

- Dust & Dust Mites – Common household dust and dust mite allergens.

- Pollen – Airborne pollen from plants, which can trigger allergies.

- Pet Dander – Tiny flakes of skin shed by cats, dogs, and other animals.

- Mold Spores – Microscopic fungi that can grow in damp environments.

- Bacteria – Many bacteria range from 0.3 to 10 microns, which HEPA filters can trap.

- Viruses (when attached to larger particles) – While most viruses are smaller than 0.3 microns, they often travel on droplets (like from sneezing) or dust, which HEPA filters can capture.

- Smoke & Soot – Particles from cigarette smoke, wildfires, or cooking.

- Tobacco Smoke Residue – Though some gaseous chemicals may pass through, the solid particles are trapped.

- Allergens – Common indoor allergens like cockroach debris.

- PM2.5 & PM10 – Fine particulate matter from pollution, vehicle exhaust, and industrial emissions.

What HEPA Filters Do NOT Capture:

- Gases & Odors (e.g., VOCs, formaldehyde, perfumes) – These require activated carbon filters.

- Ultrafine particles below ~0.1 microns (e.g., some viruses, certain fumes) – Though some may still be caught via diffusion or electrostatic attraction.

- Humidity or Water Vapor – HEPA filters don’t remove moisture.

HEPA filters are excellent for solid and liquid particles, making them ideal for allergy sufferers, asthma patients, and improving indoor air quality. For complete air purification, many systems combine HEPA with activated carbon (for gases) and UV light (for microbial control).

HEPA Filters Usage:

HEPA filters play a critical role in maintaining sterile environments, controlling contamination, and protecting patients and healthcare workers. Below are key applications in pharmacy and healthcare settings:- Laminar Airflow Workbenches (LAFWs) — for sterile compounding (USP <797>)

- Biological Safety Cabinets (BSCs) — for hazardous drug compounding (USP <800>)

- Compounding Aseptic Isolators (CAIs) / Compounding Aseptic Containment Isolators (CACIs)

- Buffer Rooms (ISO 7) and Ante Rooms (ISO 8) — cleanroom areas

- Hospital operating rooms and surgical suites — to maintain clean air over surgical sites

- Hospital isolation rooms — negative or positive pressure rooms for infection control